China Reasonable price for Carbon Foam Electrode – Factory Price High Strength Insulation Low Cement Castable – Rongsheng factory and manufacturers | Rongsheng Detail:

Low Cement Castable Description

Low cement castables are one kind of refractory castable with a high service temperature of over 1550℃, which uses aluminate cement as its binder, in which the amount of CaO is less than 2.5%. Refractory low cement castable composition mainly consists of refractory aggregate, refractory powder and water. Compared with traditional refractory castable, low cement refractory castable has a series of good performance such as low cement, low porosity, good volume stability and high cold curing-strength. And also low cement castable density is higher than other refractory castables.

Properties of Low Cement Castable

- Low water content.

- High refractoriness,

- High strength.

- Low linear change rate.

- High thermostability.

- Low porosity and High bulk density.

- High temperature strength and slag resistance.

Manufacturing Process of Low Cement Castable

Low cement castable is a castable refractory which is made of ultrafine powder, aluminate cement and some admixtures. Furthermore, the amount of these composite can influence its performance. As for its water amount, given the guaranteed ease of mixing material, adding little water can lower porosity and improve strength. Low cement refractory castable has the advantages of little amount of water, high density and high strength, which is the reason that this refractory material is widely used in many field and various furnaces and kilns.

Advantages of Low Cement Castable

High Refractory Temperature and Strength and High Anti – Slag Corrosion Resistance.

Low Porosity and High Bulk Density. During the construction process, only 1/3~1/2 amount of water for traditional castable will be added into it.

Increasing Strength With The Improving Temperature of Heat Treatment After Casting Into Shape: With proper adjustment of the castable size, it can be mixed into self-flow castable and pumped pouring material.

Rongsheng Refractory Low Cement Castable Specifications

| Item/Index | M | A1 | A2 |

| Chemical component | 65 | 80 | 90 |

| Aggregate | Mullite | Corundum | Corundum |

| Maximum service temperature | 1600 | 1700 | 1800 |

| Refractorinee | 1750 | 1790 | 1790 |

| Bulk density | 2.6 | 2.8 | 3.0 |

| Linear change after sintered | |||

| 1000℃ | -0.2 | -0.2 | -0.2 |

| 1300℃ | ±0.5 | ±0.5 | ±0.5 |

| Pressure strength after sintered | |||

| 110*24h | 30 | 30 | 30 |

| 1000*3h | 50 | 50 | 50 |

| 1400*3h | 70 | 80 | 80 |

Application of Low Cement Castable

Low cement insulation castable is widely used in many industries such as metallurgical industry, petrochemical industry, power plant, construction field and other industries. And also Low cement refractory castable can be used for furnaces and boilers in different areas according to various composition. For instance, clay and high alumina low cement refractory castable can both be used on the linings of heat furnace, soaking furnace and other heat treatment furnaces.

Low Cement Castable Manufacturer from RS Refractory Factory

RS refractory factory is a professional low cement insulation castable supplier that established in the early 90s of twenty century. RS refractory factory has specialized in low cement castables for more than 20 years. if you have some demand of refractory low cement castable, or have some questions on refractory low cement castable about physical and chemical indicators, please contact us for free. and Rs refractory factory as a professional low cement refractory castable manufacturer in china, has some competitive advantages as follows:

- Competitive Price: Make the products competitive in your market,

- Abundant Experience: Prevent cracks and twist in bricks,

- Different Moulds: Save mould fees for you,

- Strict Quality Control: Meet clients’ quality requirement,

- Large stocks: Guarantee prompt delivery,

- Professional Packing: Avoid damage and secure the goods in transportation.

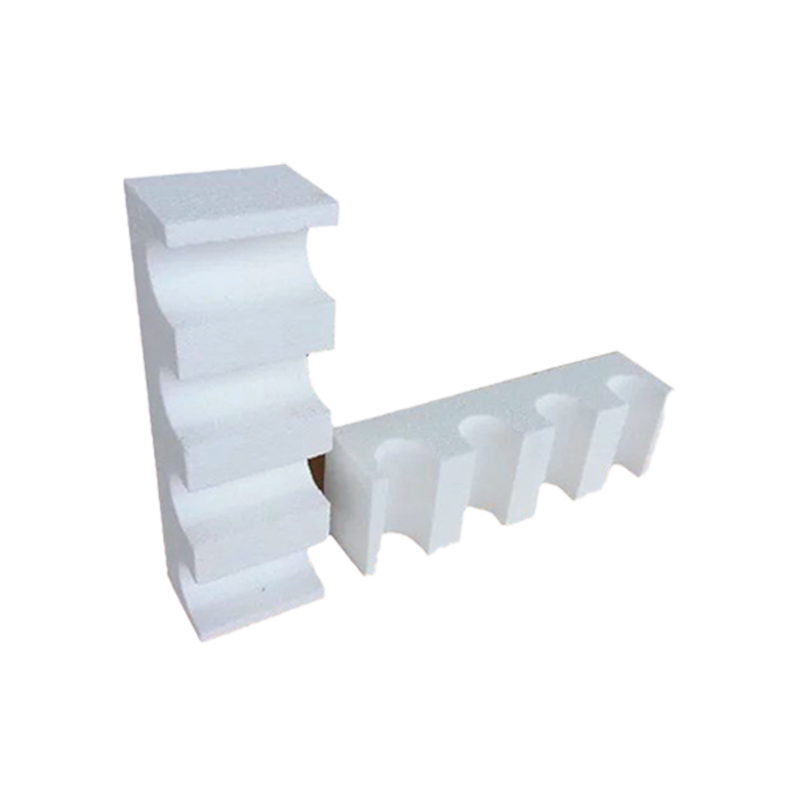

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined rate competiveness and good quality advantageous at the same time for China Reasonable price for Carbon Foam Electrode – Factory Price High Strength Insulation Low Cement Castable – Rongsheng factory and manufacturers | Rongsheng , The product will supply to all over the world, such as: New Zealand, kazakhstan, Maldives, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.