China New Arrival China High Temp Ceramic Fiber Board - Excellent heat stability Ceramic Fiber Blanket for Include Petrochemical – Rongsheng factory and manufacturers | Rongsheng Detail:

Ceramic Fiber Blanket Description

Ceramic fiber blanket is a kind of refractory insulation material with white color and regular size integrated fire resistance, heat insulation and thermal insulation. Refractory ceramic fiber blanket has refractoriness of 950~1400 ℃ and can keep the well tensile strength, toughness and fiber structure. Ceramic fiber blankets have the features of low thermal conductivity, excellent heat insulation, low thermal shrinkage, and excellent erosion resistance.

Properties of Ceramic Fiber Blanket

- Low thermal conductivity,

- Low heat capacity,

- High tensile strength,

- Excellent chemistry stability,

- Excellent heat stability,

- Excellent resistance to shock,

- Excellent sound absorption.

Manufacturing Process of Ceramic Fiber Blanket

Refractory ceramic fiber blanket adopts high strength spun ceramic fibers throng special two side needled process to improve greatly mixture degree, layered resistance, tensile strength and evenness. ceramic fiber blanket without any organic binding agent can ensure its good plasticity and stability at the high or low temperature service situation.

Types of Ceramic Fiber Blanket

- Common type ceramic fiber blanket,

- Standard type ceramic fiber blanket,

- High purity type ceramic fiber blanket,

- High alumina type ceramic fiber blanket,

- High zircon type ceramic fiber blanket.

Rongsheng Refractory Ceramic Fiber Blanket Specifications

| Item/Index | Ceramic Fiber Blanket | |||||||

| Fiber blanket 1260 | Fiber blanket 1400 | Fiber blanket 1500 | Fiber blanket 1600 | |||||

| Classification Temperature | 1260 | 1425 | 1500 | 1600 | ||||

| Melting Point | 1760 | 1800 | 1900 | 2000 | ||||

| Color | White | White | Green-blue | White | ||||

| Mean Fibre Diameter | 2.6 | 2.8 | 2.65 | 3.1 | ||||

| Fiber length | 250 | 250 | 150 | 400 | ||||

| Fiber Density | 2600 | 2800 | 2650 | 3100 | ||||

| Shot Content | 12 | 12 | ||||||

| Heat conductivity coefficient | ||||||||

| Average 400℃ | 0.08 | 0.08 | ||||||

| Average 600℃ | 0.12 | 0.12 | ||||||

| Average 800℃ | 0.16 | 0.16 | ||||||

| Average 1000℃ | 0.23 | |||||||

| Chemical component | ||||||||

| Al2O3 | 47.1 | 35.0 | 40.0 | 72 | ||||

| SiO2 | 52.3 | 46.7 | 58.1 | 28 | ||||

| ZrO2 | 17.0 | |||||||

| Cr2O3 | 1.8 | |||||||

Application of Ceramic Fiber Blanket

- High temperature duct, pipe insulation,

- Turbine insulation,

- Expansion joints & tube seals,

- Heat treatment furnaces, soaking pit cover sealing,

- Ovens and stack linings,

- Exhaust duct and Air pre-heater insulation,

- Boiler insulation,

- Fire retardant.

Ceramic Fiber Blanket Manufacturer from RS Refractory Factory

RS refractory factory is a professional ceramic fiber blanket manufacturer that established in the early 90s of twenty century. RS refractory factory has specialized in ceramic fiber blankets for more than 20 years. if you have some demand of refractory ceramic fiber blanket, or have some questions on ceramic fiber blankets about physical and chemical indicators, please contact us for free.

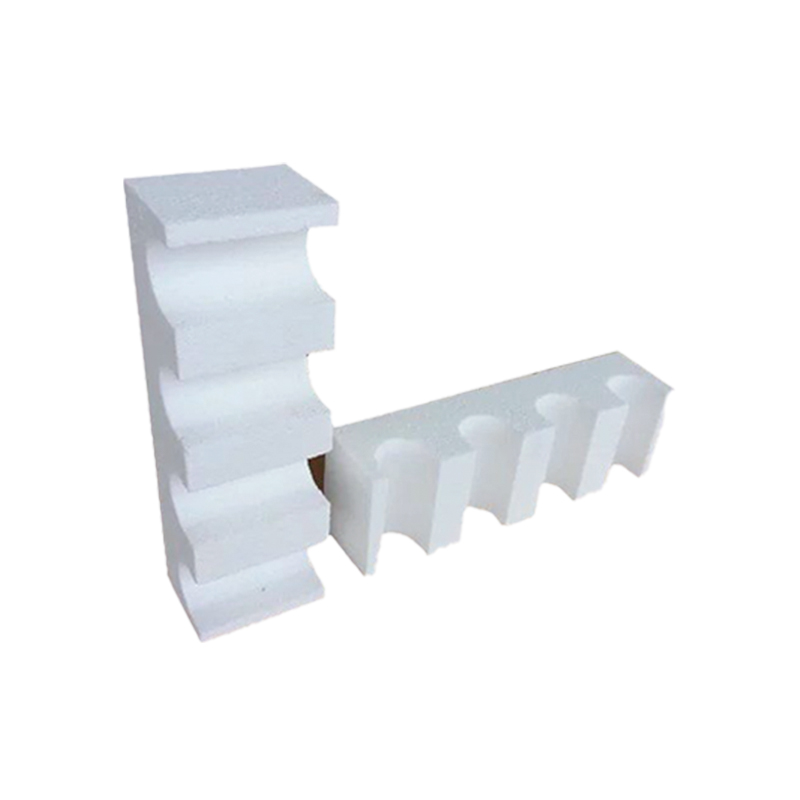

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for China New Arrival China High Temp Ceramic Fiber Board - Excellent heat stability Ceramic Fiber Blanket for Include Petrochemical – Rongsheng factory and manufacturers | Rongsheng , The product will supply to all over the world, such as: Croatia, Ukraine, Southampton, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!