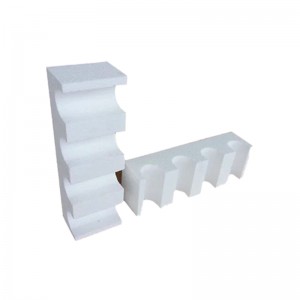

JM30 Insulation Brick Description

JM30 insulation firebrick is made from high purity refractory clays with gradually increasing aluminum oxide content and are carefully saturated with organic filling, which then burns out during the production process, resulting in a homogeneous, controlled porous structure. To achieve required tolerance, all six walls of each brick are mechanically processed.

Properties of JM30 Insulation Brick

- Excellent compression strength,

- Excellent heat stability,

- Low thermal conductivity,

- Low heat storage,

- Thermal shock stability with high strength.

Rongsheng Refractory JM30 Insulation Brick Specifications

| Index | Model | Bulk Densityg/cm3 | Reheating linear Change | Cold Crushing Strength MPa | Modulus of Rapture MPa | Thermal Conductivity 350℃ W/(m·K) |

Chemical Composition % | ||

| Al2O3 | SiO2 | Fe2O3 | |||||||

| JM30 | A | 1.0 | -0.8 1400℃*12h | 3.0 | 1.8 | 0.40 | 72 | 26 | 0.5 |

| B | 1.1 | -0.7 1400℃*12h | 3.5 | 1.9 | 0.43 | 72 | 26 | 0.5 | |

Application of JM30 Insulation Brick

JM30 insulation fire brick is widely used as the first layer of a refractory lining or as back insulating layer behind all other refractory layers in furnaces, bakes, fire channels, refining chambers and heat furnaces, regenerators, gas production plants and conduits, intended furnaces, stressrelieving furnaces, reactor chambers and similar high-temperature industrial devices.

JM30 Insulation Brick Manufacturer from RS Refractory Factory

RS refractory factory is a professional JM30 insulation refractory brick supplier that established in the early 90s of twenty century. RS refractory factory has specialized in JM30 insulation fire brick for more than 20 years. if you have some demand of JM30 insulation firebricks, or have some questions on JM30 insulation refractory block about physical and chemical indicators, please contact us for free.