China factory low price Carbon Graphite Electrode - 600*2400mm Graphite Electrode UHP Grade For Industrial Silicon Furnace – Rongsheng factory and manufacturers | Rongsheng Detail:

Graphite Electrode UHP Description

UHP graphite electrodes are made of petroleum coke, needle coke as raw material, coal pitch as binder, after calcination, ingredients, kneading, pressing, roasting, graphitization, machining and released in the electric arc furnace steelmaking in the form of an arc Electric energy as a conductor to heat the melting furnace.

Properties of Graphite Electrode UHP

- Ultra high power,

- Graphite electrode,

- Good quality,

- Competitive price.

Advantages of Graphite Electrode UHP

- The surface can be used for the long life of anti oxidation treatment,

- High temperature resistance, corrosion resistance, strong acid resistance,

- Excellent resistance to thermal shock and conduction,

- Good wear resistance, good lubricity and long service life.

Technical Characteristics of the Graphite Electrode UHP

| Name | Unit | diameter of electrode 300mm-600mm | |||

| standard | Actual measurement | ||||

| Electrode | Nipple | Electrode | Nipple | ||

| Specific electrical resistivity | μOhm • m | 6.2-6.5 | 5.5 | 5.0-6.5 | 4.5 |

| Limit of mechanical resistance to bending | MPa | 10.5 | 16 | 14-16 | 18-20 |

| Elastic modulus | GPa | 14 | 18 | 12 | 14 |

| Ash content, not more than | % | 0.5 | 0.5 | 0.5 | 0.5 |

| Bulk density, not less than | g / cm3 | 1.64-1.65 | 1.70-1.72 | 1.72-1.75 | 1.78 |

| Thermal coefficient of linear expansion (100-600 ° C) | × 10-6 / ℃ | 1.5 | 1.4 | 1.3 | 1.2 |

The Length & Diameter & Permissible Deviation of the Graphite Electrode UHP

| Diameter | Length | ||||||

| Nominal diameter | Actual diameter | Nominal length | tolerance | ||||

| Millimeters (mm) | Inch (inch) | Max. (Max.) | Min (min) | mm | Length | the maximum | |

| 300 | 12 | 307 | 302 | 1600 1800 |

± 100 | -100 | -275 |

| 350 | 14 | 357 | 352 | ||||

| 400 | 16 | 409 | 403 | ||||

| 450 | 18 | 460 | 454 | ||||

| 500 | 20 | 511 | 505 | 1600/1800/2000/2200 | ± 100 | -100 | -275 |

| 550 | 22 | 556 | 553 | ||||

| 600 | 24 | 613 | 607 | ||||

Graphite Electrode UHP Current Capacity

| Nominal diameter | Current throughput (A) | The current density (A / cm2) | |

| Millimeters (mm) | Inch (inch) | ||

| 250 | 10 | 9200-15100 | 21-30 |

| 300 | 12 | 13000-22000 | 20-30 |

| 350 | 14 | 20000-30000 | 20-30 |

| 400 | 16 | 25000-40000 | 19-30 |

| 450 | 18 | 32000-45000 | 19-27 |

| 500 | 20 | 38000-55000 | 18-27 |

| 550 | 48000-60000 | 18-24 | |

| 600 | 24 | 52000-72000 | 18-24 |

| 700 | 27th | 62000-95000 | 18-24 |

Applications of Graphite Electrode UHP

Graphite electrode uhp can be widely used in electric arc furnace and ladle refining furnace for steelmaking. uhp graphite electrodes can be widely used in the electric smelting furnace for producing the ferroalloy, pure silicon, yellow phosphorus, copper matte, calcium carbide and so on.

Graphite Electrode UHP Manufacturer from RS Refractory Factory

RS refractory factory as a professional graphite electrode uhp manufacturer in china, have many competitive advantages in the market. if you have demand of uhp graphite electrodes, or have some questions on uhp graphite electrode about physical and chemical indicators, please contact us for free, we will provide you with high quality uhp graphite electrodes.

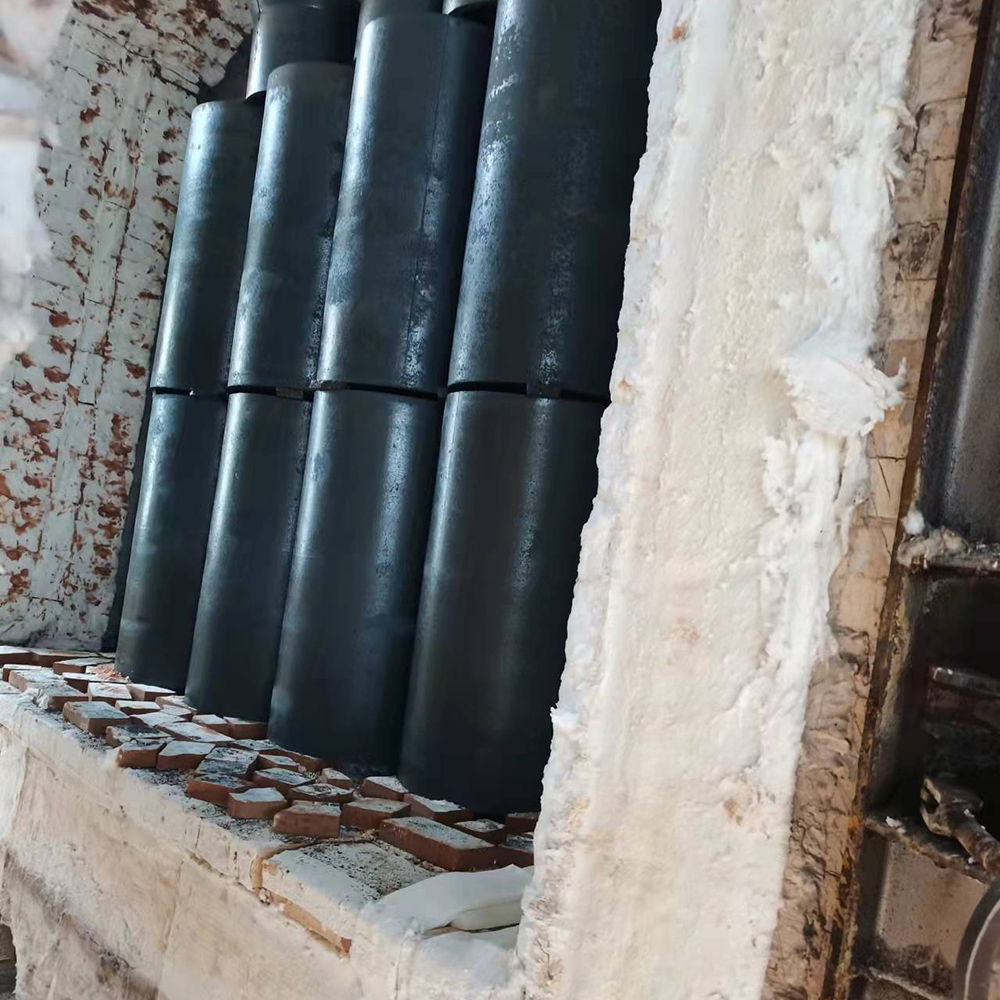

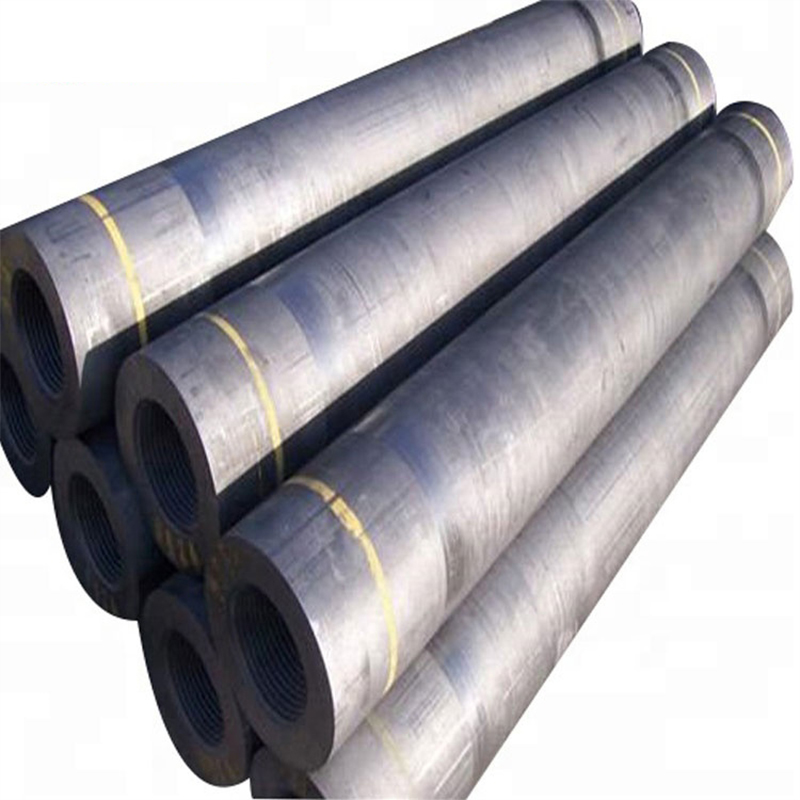

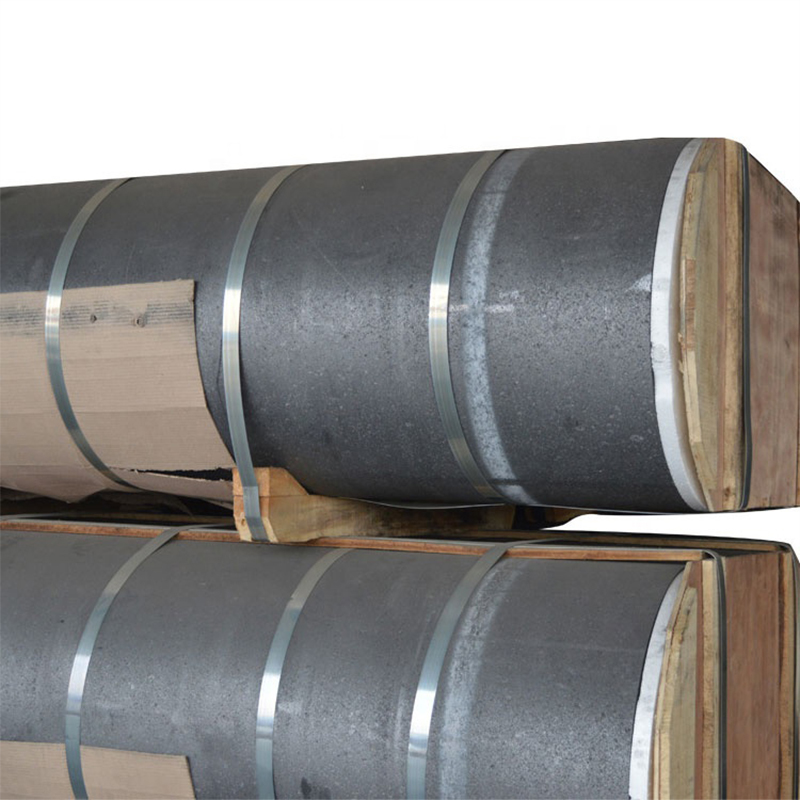

Product detail pictures:

Related Product Guide:

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for China factory low price Carbon Graphite Electrode - 600*2400mm Graphite Electrode UHP Grade For Industrial Silicon Furnace – Rongsheng factory and manufacturers | Rongsheng , The product will supply to all over the world, such as: Hungary, Seattle, Lahore, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.