China Chinese wholesale Types Of Refractory Bricks - Wear Resistant Refractory Chrome Corundum Brick – Rongsheng factory and manufacturers | Rongsheng Detail:

Chrome corundum brick refers to a corundum refractory product containing Cr2O3. At high temperature, Cr2O3 and Al2O3 form continuous solid solution, so the high temperature performance of chrome corundum products is better than that of pure corundum products. Chrome corundum fire brick is used in petrochemical gasifier should be low silicon, low iron, low alkali and high purity, and should have high density and strength.The content of Cr2O3 is in the range of 9%~15%

Chrome Corundum Brick Features

- High fire resistance,

- Big intensity,

- Good wear resistance,

- Good thermal shock resistance,

- Good acid and alkali resistance,

- Good chemical stability.

Chrome Corundum Brick Manufacturing Process

Chrome corundum brick is processed with post-al2o3, adding a certain amount of chromium oxide powder and fine powder of chrome corundum clinker, which are formed and burned at high temperature. The content of chromic oxide in sintered chrome brick is generally lower than that of fused cast chrome corundum brick. Chrome corundum block also use mud casting method of preparation, the alpha Al2O3 powder and chrome oxide powder mixing, add glue and organic adhesives made from thick mud, at the same time part of chromium corundum clinker, by grouting into adobe, firing again.

Chrome Corundum Brick Specifications

| The Specification of Chrome corundum brick | |||

| Items | Chrome-Corundum Brick | ||

| Al2O3 % | ≤38 | ≤68 | ≤80 |

| Cr2O3 % | ≥60 | ≥30 | ≥12 |

| Fe2O3 % | ≤0.2 | ≤0.2 | ≤0.5 |

| Bulk Density, g/cm3 | 3.63 | 3.53 | 3.3 |

| Cold compressive strength MPa | 130 | 130 | 120 |

| Refractoriness under Load (0.2MPa ℃) | 1700 | 1700 | 1700 |

| Permanent Linear Change(%) 1600°C×3h | ±0.2 | ±0.2 | ±0.2 |

| Apparent porosity % | 14 | 16 | 18 |

| Application | High temperature industrial furnaces | ||

Use of Chrome Corundum Brick for Furnace

Chrome corundum brick is mainly used in areas that require high abrasion and temperature resistance, such as gliding rail bricks in steel pusher metallurgical furnaces, the tapping platform style walking beam furnaces, and also as the interior for destructors, In the linings of carbon soot furnace and copper smeling furnace tapping platform of rolling mill furnace, reheating furnace skid rail.

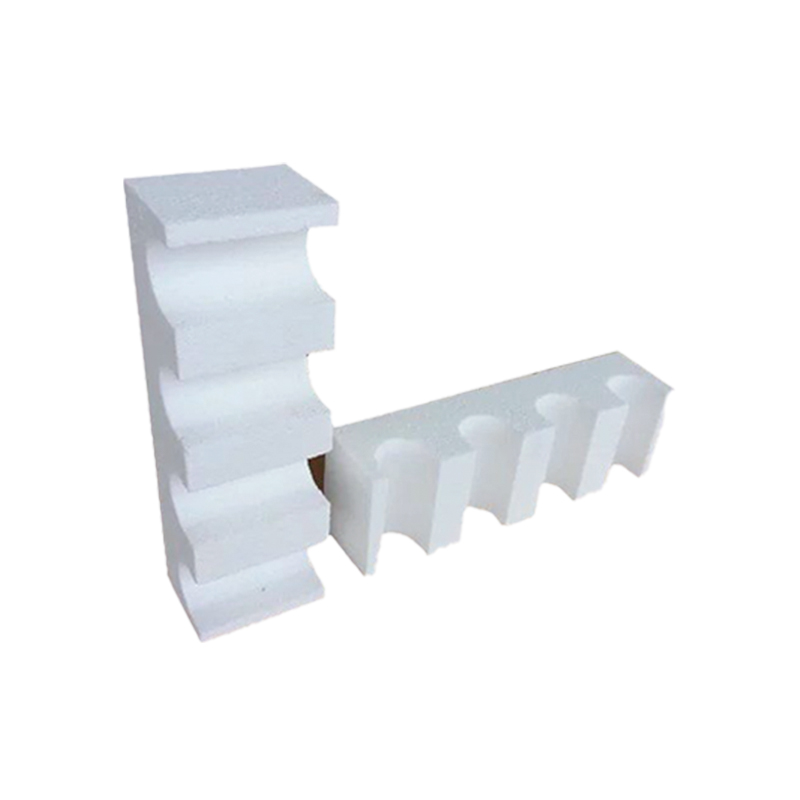

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for China Chinese wholesale Types Of Refractory Bricks - Wear Resistant Refractory Chrome Corundum Brick – Rongsheng factory and manufacturers | Rongsheng , The product will supply to all over the world, such as: Serbia, Haiti, Venezuela, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.