China 2021 High quality Magnesia Fire Brick - Low density jm26 light weight mullite thermal brick – Rongsheng factory and manufacturers | Rongsheng Detail:

JM26 Insulation Brick Description

JM26 insulation fire brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. JM26 insulation refractory brick can be used as part of the working layer of thermal insulation or non melting. JM26 insulation firebricks have been widely used in the following furnace, achieved satisfactory results. the series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials.

Properties of JM26 Insulation Brick

- Low thermal conductivity,

- Low heat storage,

- High alumina, low iron and alkali flux content,

- Accurate dimension,

- designed packaging,

- Thermal shock stability with high strength.

Rongsheng Refractory JM26 Insulation Brick Specifications

| Index | Model | Bulk Density g/cm3 |

Reheating linear Change | Cold Crushing Strength MPa | Modulus of Rapture MPa | Thermal Conductivity 350℃ W/(m·K) |

Chemical Composition % | ||

| Al2O3 | SiO2 | Fe2O3 | |||||||

| JM26 | A | 0.7 | -0.9 1400℃*12h | 2.0 | 1.2 | 0.21 | 54 | 42.5 | 0.8 |

| B | 0.8 | -0.7 1400℃*12h | 2.5 | 1.4 | 0.25 | 55 | 41.5 | 0.8 | |

| C | 0.9 | -0.5 1400℃*12h | 2.8 | 1.6 | 0.30 | 56 | 40.5 | 0.9 | |

| D | 1.0 | -0.5 1400℃*12h | 3.2 | 1.8 | 0.32 | 56 | 40.5 | 0.9 | |

Application of JM26 Insulation Brick

JM26 insulation brick is dense shaped refractory materia, with high refractoriness and mechanical behavior under high temperature, JM26 insulation refractory block is the necessary material of high temperature services, mainly used for industrial furnaces and kilns and thermal equipment. Also JM26 insulation firebricks can be used in the following place.

- Metallurgical Industry: blast furnace, hot blast furnace, heating furnace,

- Ceramic industry: roller kiln, kiln,

- Glass industry: glass furnace regenerator,

- Carbon industry: carbon furnace,

- Aluminum electrolysis industry: aluminum reduction cell,

- Other industries: tunnel kiln, shuttle kiln.

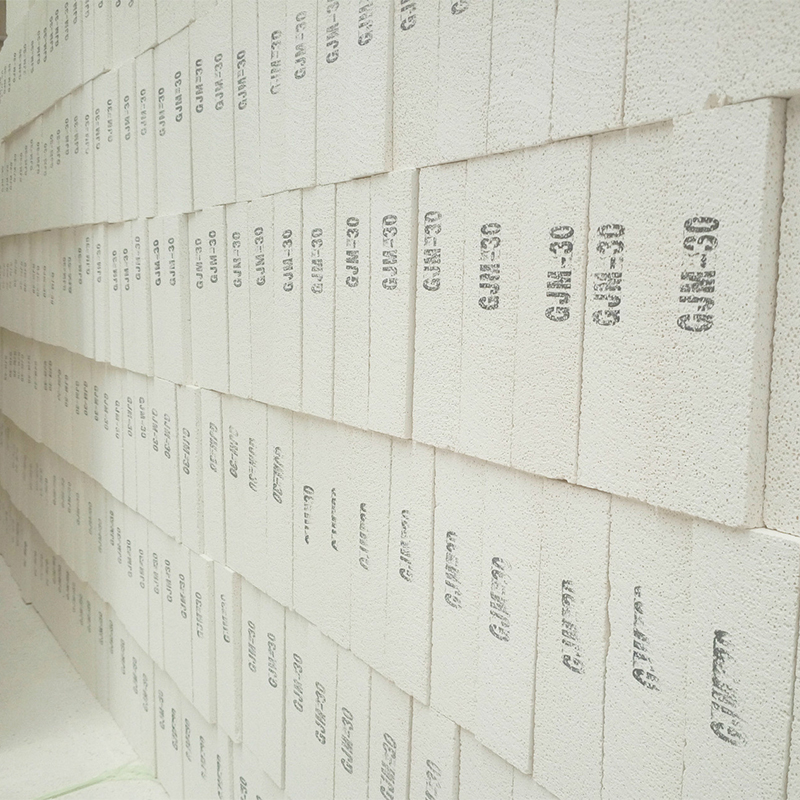

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for China 2021 High quality Magnesia Fire Brick - Low density jm26 light weight mullite thermal brick – Rongsheng factory and manufacturers | Rongsheng , The product will supply to all over the world, such as: United States, Norway, Hungary, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.